Alternatively, this post could be titled: Mundane things that add up to hurt job profitability

DIAGNOSIS OF A PROBLEM

Beginning with the introduction of Stiky Bak in the early 1980's (a transparent plastic film with adhesive on one side), the copy machine became an instrument allowing us to easily copy and place typical details or schedules onto drawing sheets. Another leap forward occurred with CAD and the ability to copy and paste information from other drawings. It was the start of the "cheapening" of information and what we didn't realize was that lurking nearby, a sinister plague began to infect our documents - that of needless redundancy.

If our documents tell the "story" of a building, many have decided that it is better told 3, 4 or even more times

When drawings were prepared by hand, redundancy had a difficult time propagating. Sheets of vellum or Mylar were expensive and it took time to generate drawings as they were created one line at a time. Changing a note or drawing was not taken lightly as an entire note might have to be erased when revising (you couldn't just edit a few words in the middle and have it automatically justified). Both vellum and Mylar had "tooth", the surface roughness that allowed them to accept pencil or pen. Too much erasing and the tooth was gone; worse yet, you might end up with a hole in the sheet! These limitations engendered an approach where you thought about what you were going to draw before committing it to paper.

DEFINITIONS

What is needless redundancy you ask? It is the populating of models and drawings with superfluous information. Examples of this are -

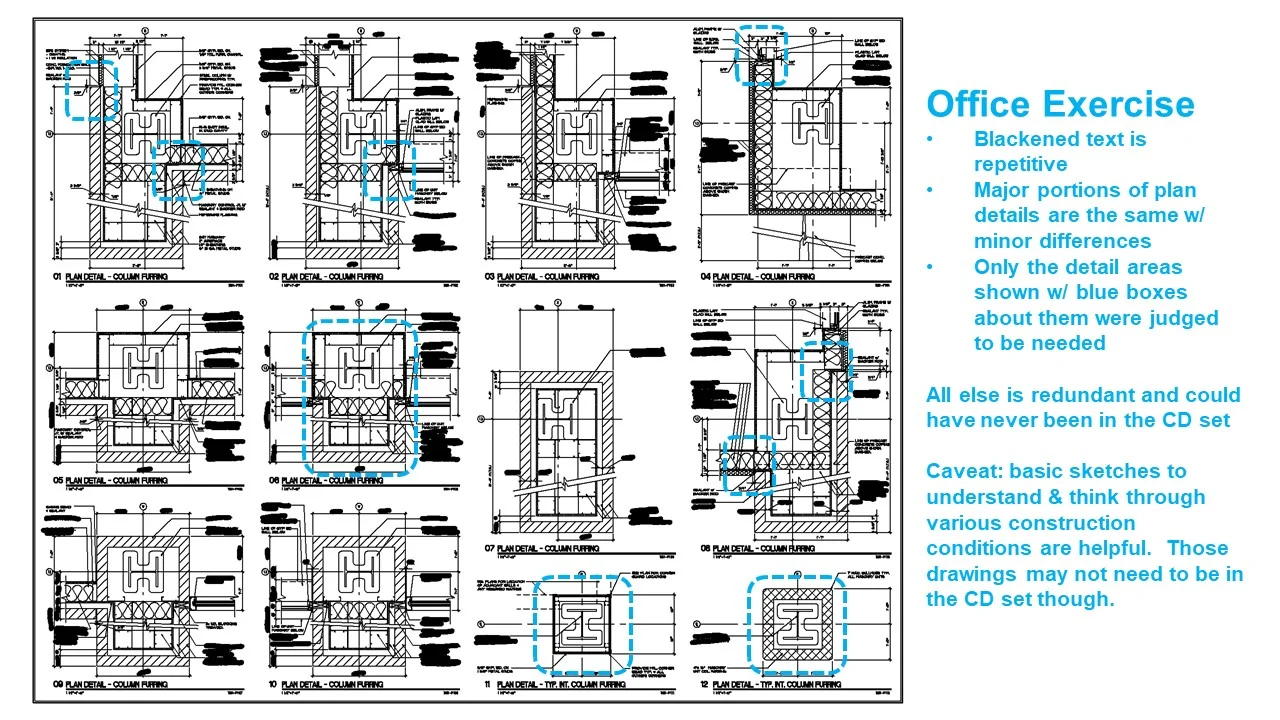

- Repetition of entire plan or section details to indicate minor differences

- Extensive annotating of interior elevations for information already noted or scheduled elsewhere (finishes scheduled on Interior's sheets or detailed descriptions of equipment already specified in another place)

- Wall sections for multi-story buildings with the same notes repeated on each floor level and on each section cut

Many are convinced that merely cutting a section or detail from the model to view and study the building automatically earns it a right to be on the CD set

SIGNAL TO NOISE RATIO

In the audio and video world, equipment is rated for its ability to clearly amplify and / or transmit signals. The amplitude of the signal is compared to that of noise and to distinguish the signal (what we really want to hear or see), its amplitude must exceed the noise - the higher the better. The term "Signal to Noise ratio" is used to express this.

Technology has let architects increase the level of noise within their documents by easily adding redundant information. Both by the graphic density within the drawings themselves and the sheer repetition of the same information in multiple locations, modern construction drawings too often lack clarity and become confusing and difficult to follow.

INBOX

On most days, I receive between 50 and 80 personal emails (not counting spam) of which probably 90% contain information on products or services I’m not interested in. One organization typically sends 3 versions of the same email on the same day, each formatted slightly differently. To get to the 5 or 6 email messages of interest, I must navigate all of them. It not only requires attention to ascertain each emails content but further action must be taken to then delete the unwanted ones. This is not unlike how our documents (drawings or specifications) become encumbered with recurring graphics and text showing and saying the same thing repeatedly and in multiple places.

You would be correct if you have noticed I am being a bit redundant here by citing examples that make the same point in a similar fashion!

DOWNSTREAM ISSUES

The more times we record the same information the greater the likelihood a mistake will be made. Everything we document, whether it is annotation or additional, similar drawings must be coordinated and checked with each other. If changes are needed, each repeating instance must be found and corrected. It is not unlike looking for Waldo amidst the sea of similar faces.

BAD BAD BAD

Is every form of redundancy bad? Not necessarily. It becomes poor practice when we needlessly repeat information readily found elsewhere. There are instances when professional judgment deems it necessary to more clearly communicate intent.

IS THERE A CURE?

One way to reduce redundancy is by implementing a systems approach to documenting. This is having a consistent and considered way of showing information that by design, prioritizes where certain types of information can be found and how it is shown. Quite often, approaches like this tend to be graphically intuitive and easy to understand by document users (and document preparers).

A good example is the use of Partition Types. This is a sheet comprised of drawings showing each type of interior partition with the pertinent data related to the walls composition including materials, thicknesses, spacings, etc. Graphically tagging the type of partition on the 1/8" floor plans only is easy to understand and follow. Additional, larger scale plan or section details in the drawing set that delineate those same interior walls need not annotate again their individual components, but can rather say – “PARTITION AS SCHEDULED”.

The concept of Default Scheduling can be layered onto systems such as these where we give the contractor the rules of the system and establish defaults – “everything is “X” unless noted otherwise”. The architects job is to find and note the exceptions. For example, adding these 3 notes to a Partition Types system can greatly reduce the amount of tagging needed on drawings with no loss of clarity or intent.

- All partitions are Type A3, unless noted otherwise. (A3 is defined on your Partition Types sheet)

- Miscellaneous non-rated chases are 5/8” gypsum board over 2 ½” metal studs, unless noted otherwise.

- Miscellaneous furring around steel columns are 5/8” gypsum board over 1 5/8” metal studs, unless noted otherwise.

A mistake quite often made with BIM is to confuse accurate modeling practices with the need to repetitively annotate everything

Redundancy will never quite be eliminated from our documents. A concerted effort to thoughtfully consider what information we show and where, and how we communicate that to contractors and AHJ’s can go a long way to making documents that are user friendly and easy to produce. It can be truthfully said that this has a benefit to the firms bottom line as well.

Next time we will discuss the glories of Football and how Lean Thinking can help in the huddle.